MOLDINO - EPSF/EPSM/ EPSW-PN | JSR GROUP

EPSF/EPSM/ EPSW-PN

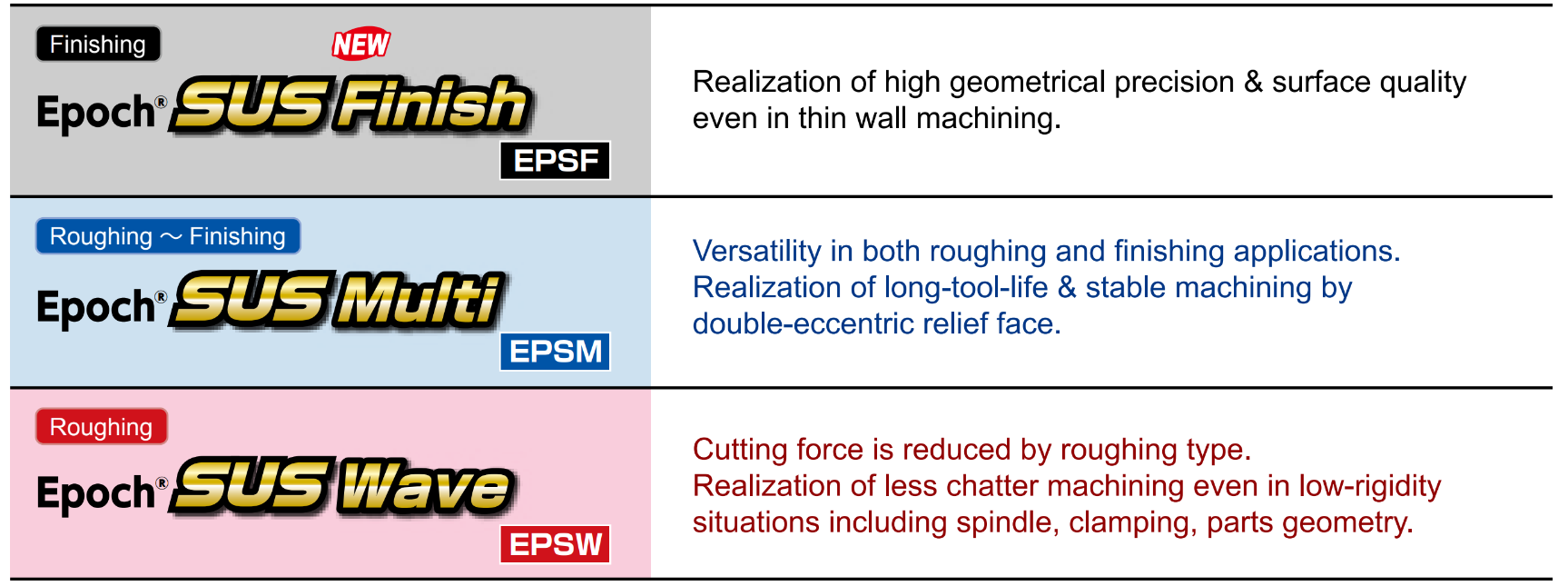

Epoch SUS Finish, Epoch SUS Multi, Epoch SUS Wave

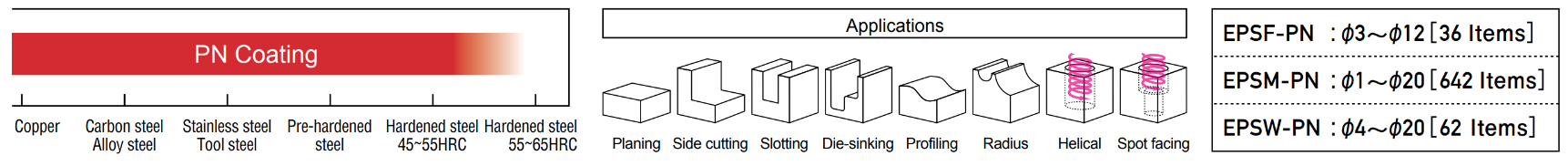

Additional lineup of Epoch SUS Finish for finishing.(size : φ3.0~12.0 36 items)

Abundant lineup! Adapt various machining from roughing to finishing.

Features of Epoch SUS series

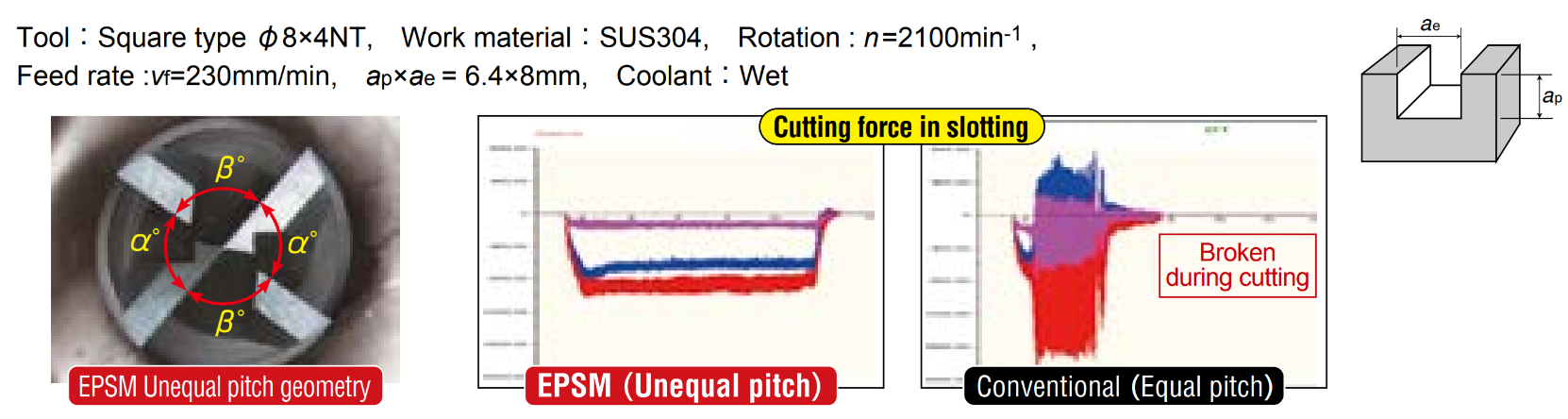

1.Suppressing vibration by unequal pitch geometry.

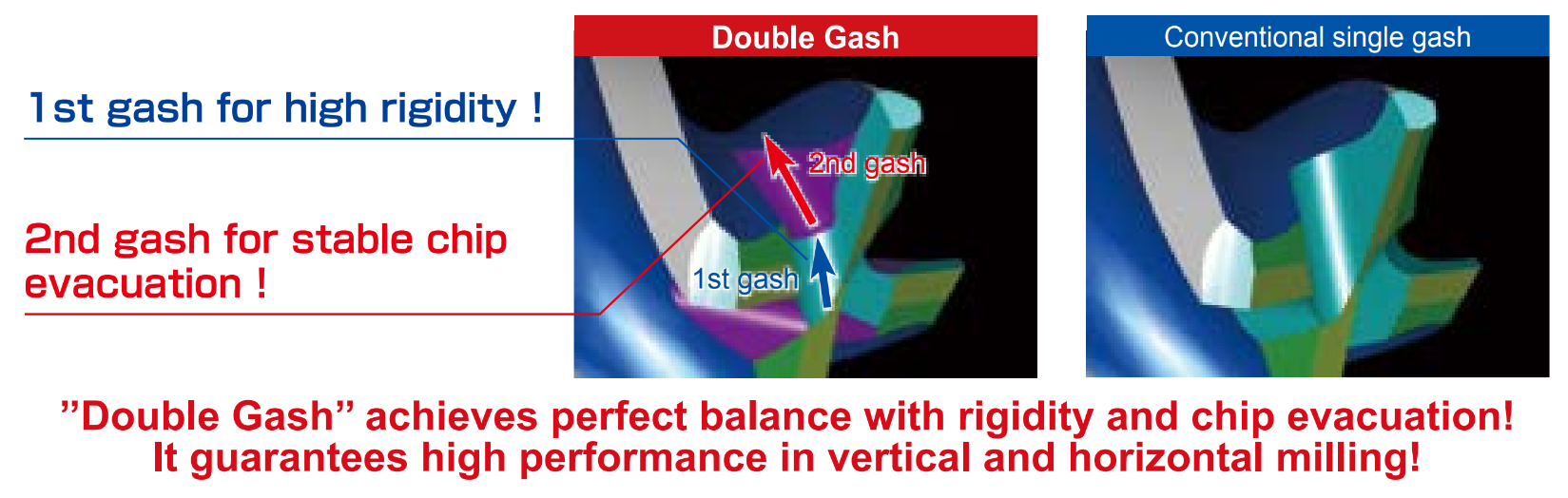

2.Smooth chip evacuation by double gash

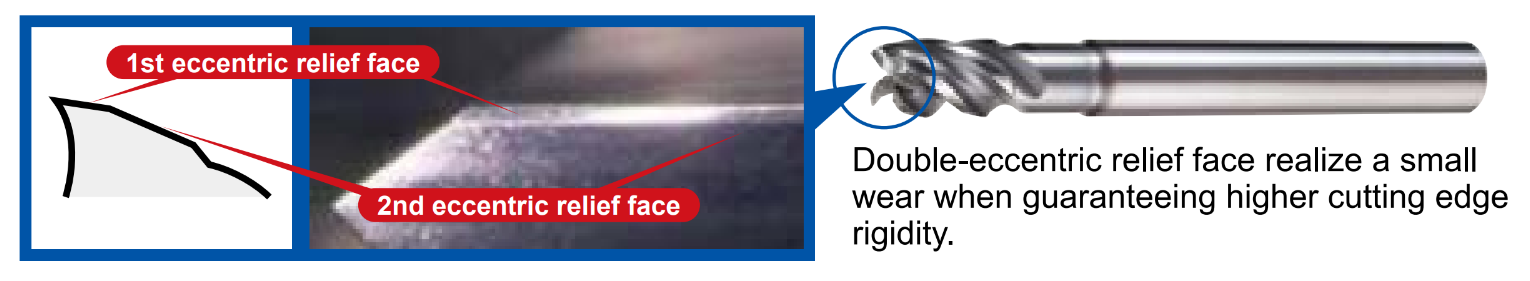

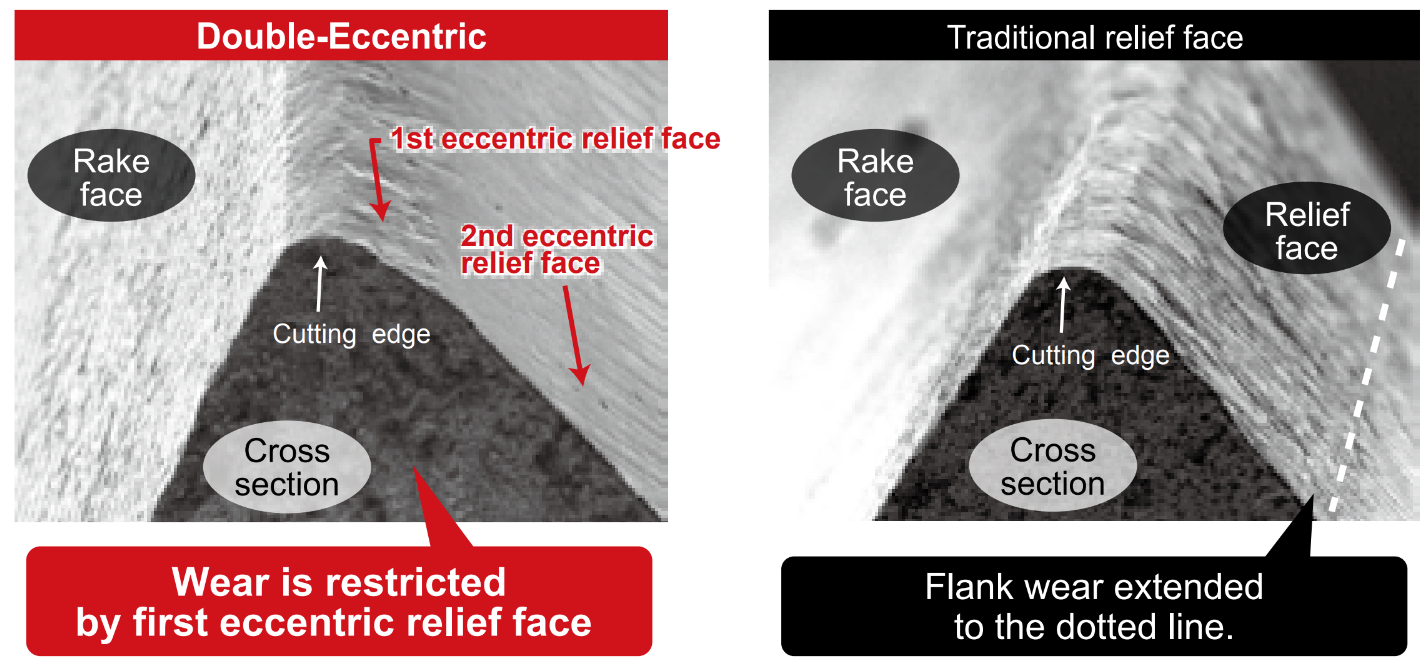

3.Improving chipping-resistance & wear-resistance by double-eccentric relief face.

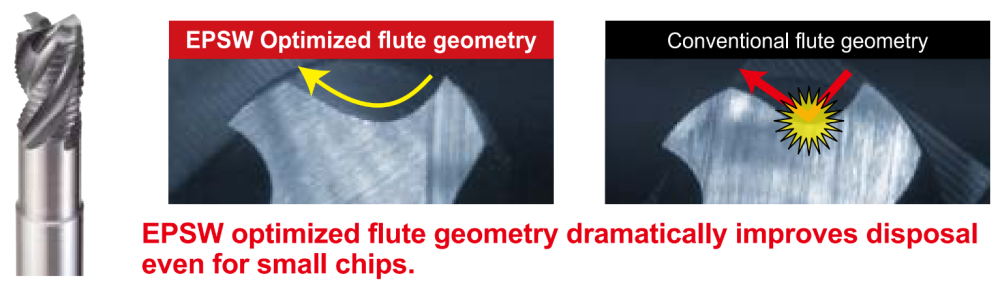

4 Smooth chip evacuation by optimized flute geometry

5.Improving wear-resistance and tool life by PN Coating.

| Overview of Epoch SUS Series |

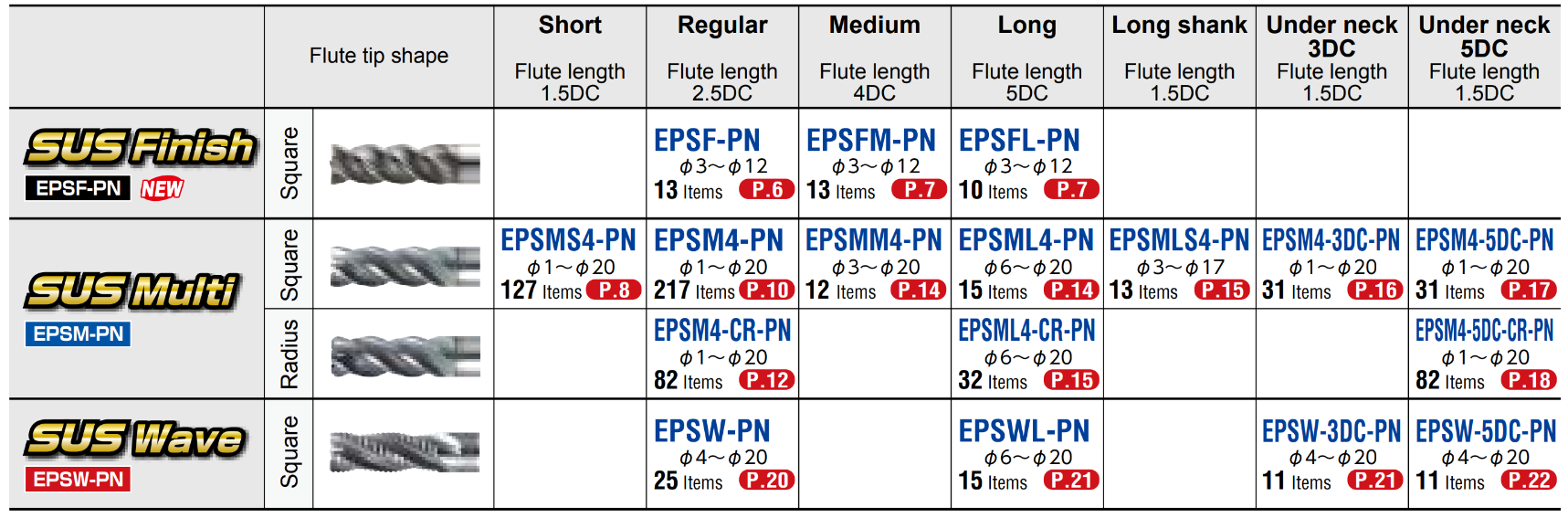

| Line-ups of Epoch SUS seriesLine-ups of Epoch SUS series |

| Features | 01 | Unequal pitch geometry Dramatically suppressing vibration |

| Features | 02 | Double Gash Smooth chip evacuation |

| Features | 03 | Introduction of Double-eccentric relief face Improving chipping-resistance & wear-resistance |

| Wear status after SUS304 side millin |

| Features | 04 | Optimized Flute geometry Smooth chip evacuation |

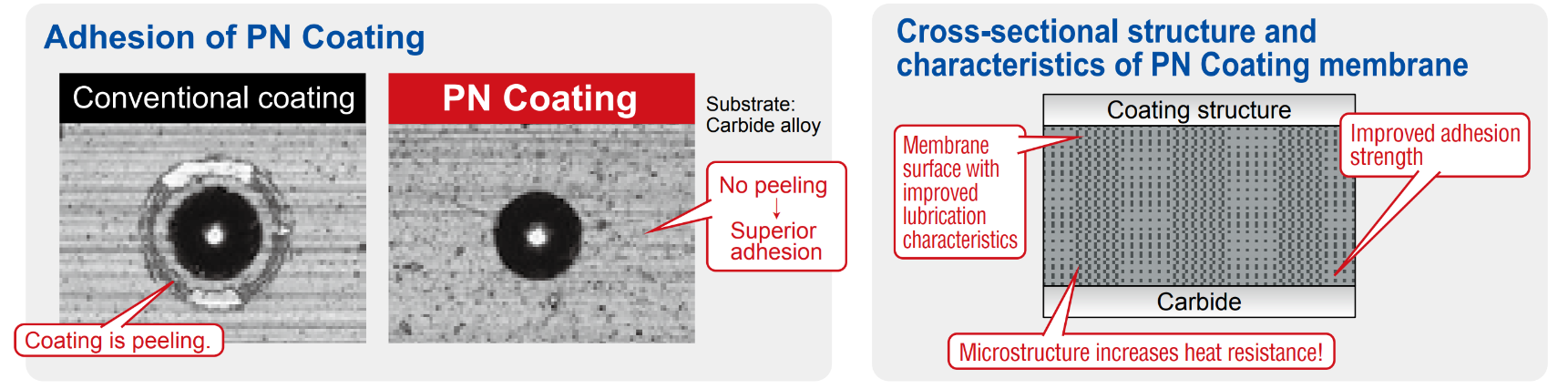

| Features | 05 | PN Coating Improving wear-resistance and tool life |

| Features and characteristics |

・A heat-resistant coating material with excellent adhesion to the tool substrate was achieved by optimizing the Al content.

・Exhibits excellent cutting life for cutting materials such as plastic molds, etc. where tool seizure often occurs. Provides the long life in cutting processing of materials starting with HPM-MAGIC and including pre-hardened steel,carbon steel, alloy steel, SUS, SKD61, SKD11, etc.

Note) This product obtains less electric conductivity. Therefore, Please caution of using electric transmitted measuring systems.

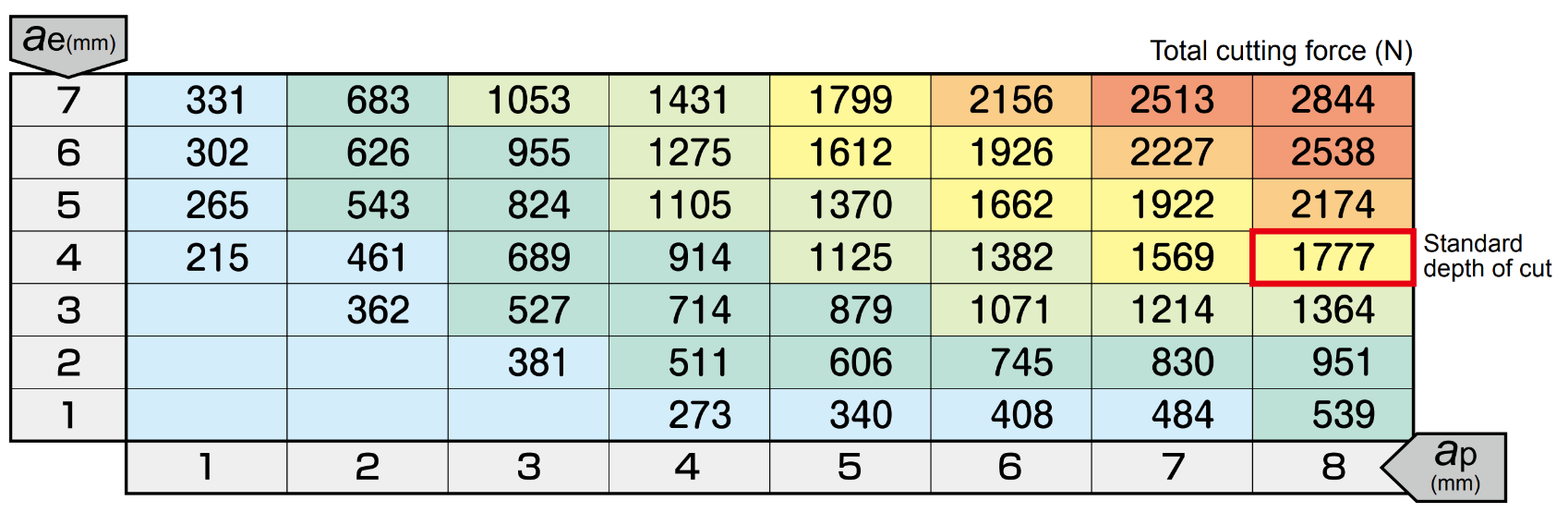

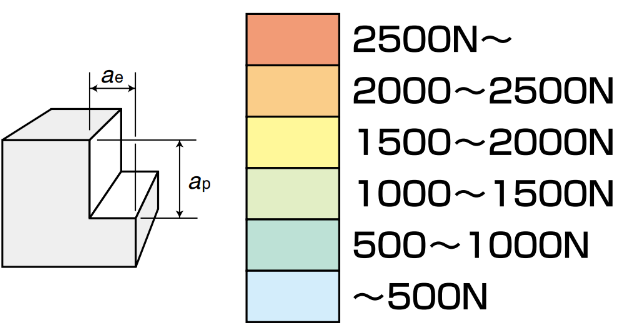

| Cutting force comparison by cutting depth amount (when performing side cutting with φ8mm tool) |

Epoch SUS Multi ap & ae EPSM

EPSM4080-24-PN

|

|

※Value indicates total cutting force. ※The chart was created beased on experimental data only for reference, please adjust according to user’s own cutting situation. |

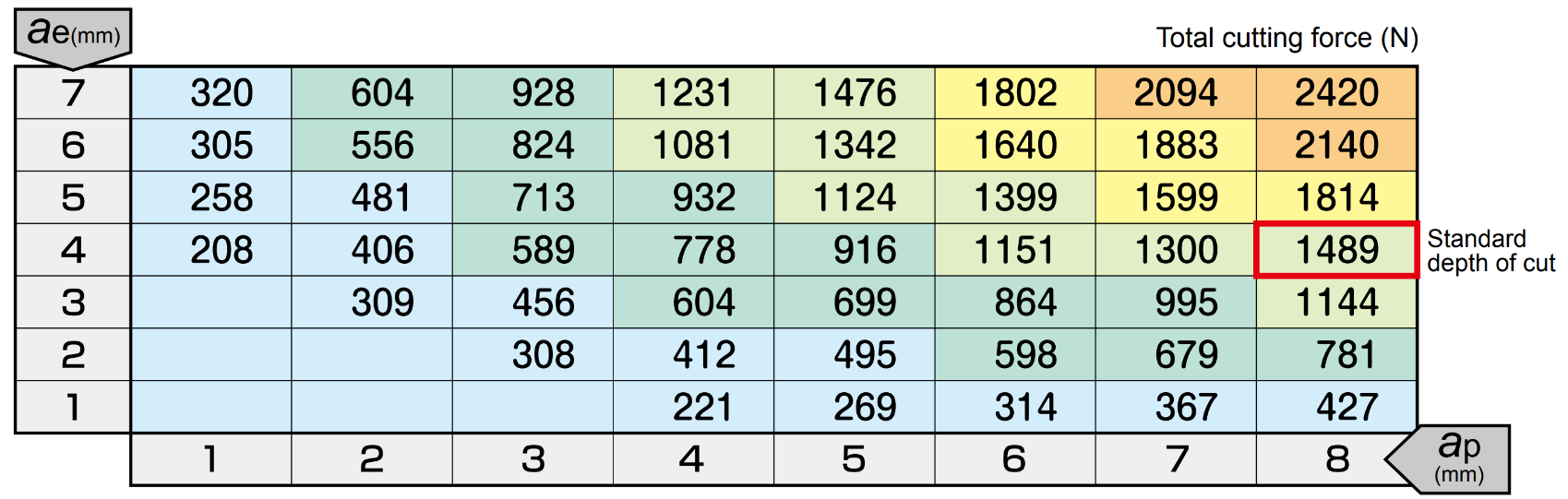

Epoch SUS Wave ap & ae EPSW

EPSW4080-24-PN

|

|

EPSW provides lower cutting force at the samecutting depth. |

|

This table can be reference data for comparing cutting force based on different ap & ae. Lower cutting force could lead to more stable machining. ①If Φ8 endmill with ap=7mm & ae=3mm can lead to a machining. Cutting force of ap=4mm & ae=5mm could be same level. |